-40%

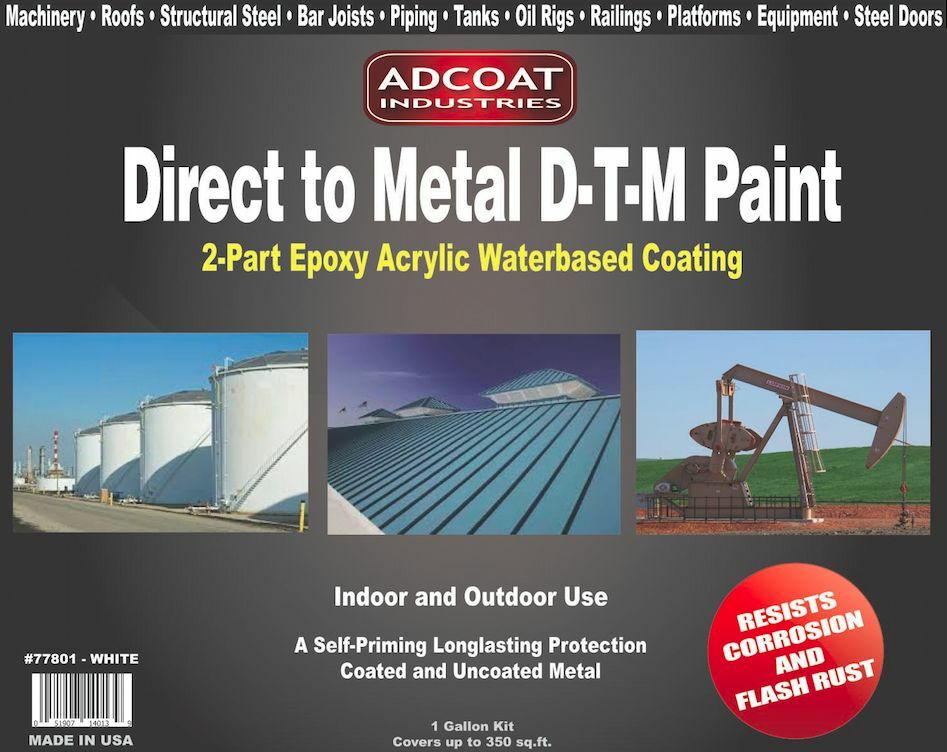

Direct to Metal DTM Paint: 2-Part Epoxy Coating, Interior/Exterior -1g, White

$ 47.46

- Description

- Size Guide

Description

ADCOAT DIRECT TO METAL DTM PAINT2-Part Epoxy Acrylic Waterbased Coating

Two Parts Are Stronger Than One!

Protects metal for over 10 years

Available in 1 gallon (77801), 5 gallon (77805) kits.

**Other products and sizes available -- please visit

our eBay store

.**

Made in the USA.

Adcoat’s Direct to Metal DTM Paint - 2-Part Epoxy Acrylic Waterbased Coating

is a tintable, two-component, waterbased coating which uses a 100% pure epoxy catalyst to ensure an extremely durable, strongly bonded paint finish to metal surfaces.

The addition of acrylic resin provides added durability and the versatility for outdoor application longevity.

The cured finish easily stands up to the harshest of environments.

While other epoxy coatings fade and chalk when exposed to sunlight and certain interior lighting conditions, the unique formulation of

Adcoat’s Direct to Metal DTM Paint - 2-Part Epoxy Acrylic Waterbased Coating

allows indoor and outdoor application without these signs of degradation. This same coating has been tested on the North Sea Oil Rigs lasting over 10 years with no signs of peeling.

This versatile product creates a tough, durable, protective surface designed to provide lasting protection for painted and unpainted

metal

items exposed to light to heavy industrial situations including tanks, oil rigs, metal railings, decks, iron work, framing and equipment.

The 2-parts are easily mixed and applied using standard painting methods for metal.

PERFORMANCE FEATURES

Long-Term Resistance to Chemicals Abrasion and Impact Resistant Protects Against Corrosion

Tolerant of Humid Conditions Provides Superior Bond Adhesion

Self Priming Formulation

Blocks Flash Rust Bleed Through Flash Rust Inhibitor Interior / Exterior

Industrial Strength - Light to Heavy Waterbased / Environmentally Friendly

Safer Than Solvent Based Coatings

Fast Dry - Low VOC – Low Odor Non-Hazardous Non-Flammable

Non-Corrosive Easy Application – Pre-measured Kit Brush, Roller or Spray Application

Non-Fading Color Long Pot Life (6 Hours) Soap and Water Clean Up

ADCOAT Direct to Metal DTM Paint - 2-Part Epoxy Acrylic Waterbased Coating

can be applied to a variety of

interior

and

exterior

surfaces offering superior corrosion protection as well as chemical and abrasion resistance for metal components and structures. The cured finish will resist gasoline, oil, transmission fluid, salt water, bleach and many other solvents/chemicals. It will extend the life of metal equipment by protecting it from rust and future corrosion by sealing out moisture.

Designed for new construction or maintenance applications, the product is self-priming and can be used directly over a wide variety of properly prepared substrates in the marine, industrial, machinery, farming, household, automotive and construction sectors.

Steel

Galvanizing (weathered)

Aluminum

Buildings

Equipment

New Construction

Machinery

Piping

Structural Steel

Power Plants

Water Treatment Plants

Marine Structures

Storage Tank Exteriors

Conforms to AWWA D102-03 OCS #3 - Acceptable for use in high performance architectural applications.

Read All Directions and Limitations Before Use!

SURFACE PREPARATION

:

The type and extent of surface preparation will vary with the nature of the surface, its condition and the type of exposure. The primary purpose of surface preparation is to remove all contaminants that would hinder proper adhesion and to render a sound clean substrate suitable for firm bonding. All surfaces must be clean, dry and free of dust, oil, grease, form releases, wax, polish, mold/mildew, loose rust scale, loose or peeling paint, salts and other debris or surface contaminants.

Clean with a strong detergent or power wash to clean surface. For heavy oil deposits several cleanings may be necessary.

Warning:

If you scrape sand or remove old paint from any surface, you may release lead dust. LEAD IS TOXIC. EXPOSURE TO LEAD DUST CAN CAUSE SERIOUS ILLNESS, SUCH AS BRAIN DAMAGE, ESPECIALLY IN CHILDREN. PREGNANT WOMEN SHOULD ALSO AVOID EXPOSURE. Wear NIOSH-approved respirator to control lead exposure. Carefully clean up with a wet mop or HEPA vacuum. Before you start, find out how to protect yourself and family by contacting the U.S. EPA/Lead Hotline at 1-800-424-LEAD (5323) or log on to

www.epa.gov/lead

For old metal surfaces

-- Clean and remove heavy rust (or use Adcoat’s Rust Converter and Primer).

On previously coated metal surfaces

-- should have all peeling and scaling paint removed by a mechanical grinder, high pressure washer equipment, or sandblasting. Surface must then be cleaned. Rinse thoroughly and allowed to dry completely before painting.

MIXING:

Mix Part A with Part B as supplied.

Stir thoroughly for at least five minutes by hand or 2 minutes with a drill mixer. The product has a pot life of 6 hours so do not use product after this time.

APPLICATION

: Apply with a brush, roller or airless paint sprayer (tip size 019-021) in one continuous coat measuring 5-8 mils wet thickness. Make sure no pinholes or air bubbles are left on the coating. Check mils thickness throughout application making sure to recoat where mil reader cuts into surface.

Two coats are recommended.

For ease of application, up to ½ pint of water per gallon may be added. A test patch is always recommended.

COVERAGE

:

Up to

200

sq. ft. /gallon first coat and up to 300 sq. ft. per gallon on second coat. Estimates are dependant upon surface condition and profile and do not account for surface irregularity, porosity, of substrate, applicator technique or overspray.

DRY TIME

: Dependant upon temperature and/or weather conditions.

To Touch - 2 hours // Dry Hard - 12 hours // Full Cure - 7 days.

CLEAN UP

:

Clean spills/splatters and equipment immediately with soap and water. If it sets-up or dries use mineral spirits or lacquer thinner to remove.

SHELF LIFE:

Up to 2 years from the date of manufacture when properly stored.

LIMITATIONS:

DO NOT store below 45°F or above 90°F.

DO NOT apply over frozen or frosted substrates.

DO NOT reuse empty container. Recycle or dispose of material properly.

DO NOT apply if rain is forecasted within 24 hours.

DO NOT thin, add or mix any material with the coating unless approved by manufacturer.

DO NOT paint in direct sun or on hot surfaces that exceed 90°F.

DO NOT use acetone or mineral spirits for surface preparation.

PRODUCT DATA:

Weight: 8.85 lbs./gallon

Conforms to ASTM D 1475

VOC: <50 g/L

Conforms to ASTM D 3960

Viscosity: 55±2 KU

Fire Rating: Class A

Conforms to ASTM E 84

SAFETY INFORMATION SUMMARY:

Keep out of reach of children.

Do not take internally.

Keep from freezing.

Read the material Safety Data Sheet (MSDS) for this product prior to use.

Contain spilled material and remove with inert absorbent. Dispose of contaminate absorbent, container and unused contents in accordance with local, state and federal regulations.

WARNING! MAY CAUSE SKIN OR EYE IRRITATION.

CAUTION!

Do not take internally. Avoid contact with eyes and skin. Wear protective clothing, gloves and eyewear. Wash hands after using. If you experience eye watering, headaches, or dizziness, increase fresh air, or wear respiratory protection. Keep container closed when not in use. Do not transfer contents to other containers for storage.

First Aid:

In case of contact with eyes and/or skin, flush area with clean water for a minimum of 15 minutes and, if irritation persists, seek medical attention. If ingested, seek medical attention immediately.

LIMITED WARRANTY

Adcoat Industries LLC warrants that this product meets manufacturing specifications. If this product does not meet these specifications, the manufacturer will, at its option and upon proof of purchase, either furnish an equivalent amount of new product to you or refund the purchase price of this product. Adcoat Industries LLC will not be responsible for (1) labor or the cost of labor for the removal or application of any product; (2) delivery delays or any costs incurred due to delivery delays.; or (3) any incidental or consequential damages, weather based on breach of expressed or implied warranty, negligence, strict liability, or any other legal theory.

It is our goal to provide our customers with accurate information. To the best of our knowledge, the data contained herein is true and accurate at the date of issuance, but is subject to change without notice. Data reflects information obtained through testing performed at optimum conditions. Actual results may vary.