-40%

EPOXY RESIN FOR PRINTED CIRCUIT BOARD POTTING COMPOUND ENCAPSULATING WATERPROOF

$ 18.33

- Description

- Size Guide

Description

MAX MCR A/BPOTTING RESIN FOR ELECTRONIC CIRCUIT BOARDS

48-OUNCES COMBINED VOLUME

1 QUART OF RESIN

AND

1 PINT OF CURING AGENT

Electrical Insulating And Potting Of Electronic Circuitry

Permanent Opaque Black Masking Compound For Proprietary Designs

Embedding Or Masking Compound

Waterproof Or Continuous Water Immersion

Salt Or Freshwater

Suitable For Low To High Voltage (Up To 500 Volts Per Mil)- AC/DC Circuit

RoHS Compliant -

Restriction of Hazardous Substances Directive 2002/95/EC

PRODUCT DESCRIPTION

MAX MCR A/B is an unfilled medium working time, low viscosity potting compound resin system for embedding or encapsulating printed circuit boards (PCB), relays, coils, and other electronic components and circuitry.

MAX MCR A/B is low in viscosity and it is room temperature cured (50°F to 90°F). It is mixed 2:1 by weight or by volume and provides a 30 minute working time (200-gram mass).

The mixed consistency is similar to that of mineral oil and it is poured in place, injected or it is adaptable for mix meter dispensing equipment.

MAX MCR is completely non-electrically conductive that prevents direct physical contact with the circuitry. It cures to a hard and tough compound that is suitable potting small to medium parts up to 6 ounces (180 grams) in mass without excessive exothermic heat generation. It provides a 30-minute working time when mixed up to 200-gram mass.

MAX MCR A/B bonds to PVC, PP, ABS, plastisol, aluminum, steel, copper, brass and other materials typically used in electrical assembly and printed circuits boards.

Upon cure, MAX MCR A/B is hard and waterproof suitable for continuous water immersion and exposure to harsh environments that protects electrical connections from c.

Its opaque black color permanently masks proprietary

circuit

and electronic components from.

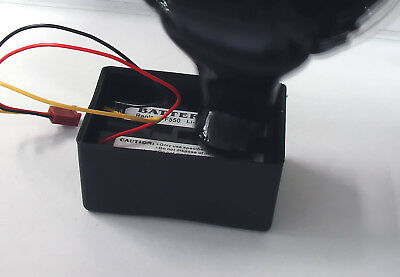

HIGH-PRESSURE SENSORS POTTED WITH MAX MCR A/B

>2,000,000 CYCLIC ON/OFF TEST WITH NO FAILURE

24 VOLT SOLENOID VALVE POTTED WITH MAX MCR A/B.

THIS KIT INCLUDES A SET OF YORKER CAPS FOR CONTROLLED DISPENSING.

Use these Yorker caps to dispense the material with ease and minimize over pouring and reduce spills. C

ut the tapered tip to meter the orifice of the tip for accurate dispensing. When done, just replace the tip cap and it will exclude ambient moisture and air and keep the resin system viable for years.

We do not recommend using dispensing pumps. The curing agent or part B of any epoxy resin system is sensitive to moisture and carbon dioxide, which will react with the curing agent and form carbamate crystals (salt-like crystals that form on the tip of the pump) and reduce reactivity.

Unless the kit is used continuously and within a short period of time, using dispensing pumps will cause more problems than ease-of-use.

MAX MCR PHYSICAL PROPERTIES

AND

CURED MECHANICAL PROPERTIES

F

orm And Color

Black Liquid, Self Leveling Other Colors Available

Viscosity Part A

2,500 cPs

@75°F

Viscosity Part B

750 cPs

@75°F

Mixed Viscosity

1,950 cPs

@75°F

Mix Ratio By Weight

(2:1) 100 Parts A to 50 Parts B

Mix Ratio By Volume

(2:1)100 Parts A to 50 Parts B

Mixed Density

1.10 g/cc

Working Time

30 minutes (400-gram mass)

Gel Time

60 minutes

@75°F

Peak Exotherm

280°F max (400-grams)

Demold Time

24 hours room temperature

@75°F

Accelerated Cure

2 Hours @75°F

+30 minutes @200°F

Shore Hardness

75 Shore D

Shrinkage:

<0.30 %

Compressive Strength

13,800 psi

@75°F

Tensile Strength

9,900 psi

@75°F

Tensile Elongation

4%

@75°F

Heat Distortion Temperature

190°F

ELECTRICAL AND THERMAL CONDUCTIVITY PROPERTIES

Volume Resistivity

4.7 X 10

13

Ohms-Cm

Dielectric Strength

510 Volts/Mil 60 Cycles

Dielectric Constant

4.0 (10 kHz)

Dissipation Factor

0.014 (10 kHz)

Thermal Conductivity (Unfilled) 40°-45°C

0.25 W F/mK

CHEMICAL RESISTANCE PERFORMANCE

FULL IMMERSION AT 25°C

MEASURED PERCENT CHANGE IN WEIGHT

Reagent

10 days

28 Days

Deionized Water

0.03 %

0.03 %

Sea Water

0.01 %

0.08 %

Methanol

0.93 %

-2.41 %

Ethanol

1.98 %

1.28 %

Toluene

0.40 %

2.86 %

Xylene

0.04 %

0.05 %

Gasoline (E85 Blend)

0.10 %

0.03 %

Dimethyl Formamide

Destroyed

Destroyed

10% Lactic Acid

0.81 %

1.42 %

10% Acetic Acid

0.11 %

0.45 %

70% Sulfuric Acid

0.08 %

0.14 %

50% Sodium Hydroxide

0 %

0.1 0%

10% Sodium Hypochlorite

0.51 %

0.96 %

CIRCUIT BOARD POTTING

WATERPROOFING OF AN ELECTRICAL CIRCUITRY

MAX MCR A/B POTTING AND ELECTRONIC ENCAPSULATION

MAX MCR A/B used as the black PCB potting compound.

The clear resin used as the LED encapsulant is our MAX DIAMOND CLEAR, a cycloaliphatic epoxy resin that is resistant to degradation from UV energy produced by the LED light.

It

demonstrates excellent transparency and color stability suitable for LED encapsulation.

MAX DIAMOND CLEAR A/B 48 OUNCE KIT

CRYSTAL CLEAR LED BULB ENCAPSULANT

MAX MCR A/B IS WELL SUITED FOR AUTOMOTIVE ENVIRONMENT

(195°F SERVICE TEMPERATURE)

EPOXY RESIN MIXING AND USAGE APPLICATIONS

The use of a weighing scale is highly recommended for proportioning the 2:1 mix ratio. Using volumetric measuring is fine, however, weighing the resin and curing agent yields better-cured mechanical properties, batch repeatability, and less waste from mixing over-sized batch. Use this digital scale to precisely weigh the resin and curing agent and ensure full polymerization of the resin and curing agent and prevent leaching.

Purchase this scale with any of product offering and the shipping cost of the scale is free.

Please request a total before paying for combined shipping savings.

https://www.ebay.com/itm/222630300203

EPOXY RESIN MIXING AND THICK CASTING TROUBLE-FREE TECHNIQUE MAX MCR A/B RESIN SYSTEM - YouTube

Video will open in a new window

[isdntekvideo]

Please View The Following Video For The Proper Mixing Of Epoxy Resins. It Demonstrates The Proper Technique Of Mixing Any Type Of Epoxy Resin. The Proper Cure And Final Performance Of Any Epoxy Resin System Is Highly Dependent On The Quality And Thoroughness Of The Mix. The Resin And Curing Agent Must Be Mixed To Homogeneous Consistency.

EVIDENCE OF POOR MIXING

Video will open in a new window

The Proper Cure And Final Performance Of Any Epoxy Resin System Is Highly Dependent On The Quality And Thoroughness Of The Mixing Quality. The Resin And Curing Agent Must Be Mixed To Homogeneous Consistency To Achieve Proper Cure And Tack Free Results.

Click Window To Watch Video Demonstration

How To Mix Epoxy Resin For Food Contact Coating. Avoid Tacky Spots, Minimize Air Bubble When Mixing - YouTube

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]

PLEASE CHECK OUT OTHER AVAILABLE

RESIN SYSTEMS AT OUR eBay STORE

For our complete listing, please

Visit our eBay store!

DON'T FORGET OUR EPOXY MIXING KIT

Click The Link To Add To Order

https://www.ebay.com/itm/222623932456

EVERYTHING YOU NEED TO MEASURE, MIX, DISPENSE OR APPLY

Proportioning the correct amount is equally as important to attain the intended cured properties of the resin system.

T

he container in which the epoxy and curing agent is mixed is an important consideration when mixing an epoxy resin system.

The container must withstand the tenacity of the chemical and must be free of contamination.

Most epoxy curing agent has a degree of corrosivity, as a general practice, protective gloves should be worn when handling chemicals of the same nature.

MIXING KIT CONTENTS

1 Each Digital Scale -Durable, Accurate Up To 2000.0 Grams

4 Each 32-ounce (1 Quart) Clear HDPE Plastic Mix Cups

4 Each 16-ounce (1 Pint) Clear HDPE Plastic Mix Cups

One Size Fits All Powder-Free Latex Gloves

2 Each Graduated Syringes

Wooden Stir Sticks

Assorted Size Foam Brush

IMPORTANT NOTICE

Your purchase constitutes the acceptance of this disclaimer. Please review before purchasing this product.

The user should thoroughly test any proposed use of this product and independently conclude the satisfactory performance in the application. Likewise, if the manner in which this product is used requires government approval or clearance, the user must obtain said approval.

The information contained herein is based on data believed to be accurate at the time of publication. Data and parameters cited have been obtained through published information, PolymerProducts and Polymer Composites Inc. laboratories using materials under controlled conditions. Data of this type should not be used for a specification for fabrication and design. It is the user's responsibility to determine this Composites fitness for use.

There is no warranty of merchantability for fitness of use, nor any other express implied warranty. The user's exclusive remedy and the manufacturer's liability are limited to refund of the purchase price or replacement of the product within the agreed warranty period. PolymerProducts and its direct representative will not be liable for incidental or consequential damages of any kind. Determination of the suitability of any kind of information or product for the use contemplated by the user, the manner of that use and whether there is any infringement of patents is the sole liability of the user.